LEAN Principles

What is a LEAN Process?

Small and large facilities alike are burdened by disorganization, inefficient resource management, and high amounts of waste, which can lead to a decline in employee morale and productivity, as well as a decrease in the facility’s ability to operate at its true potential.

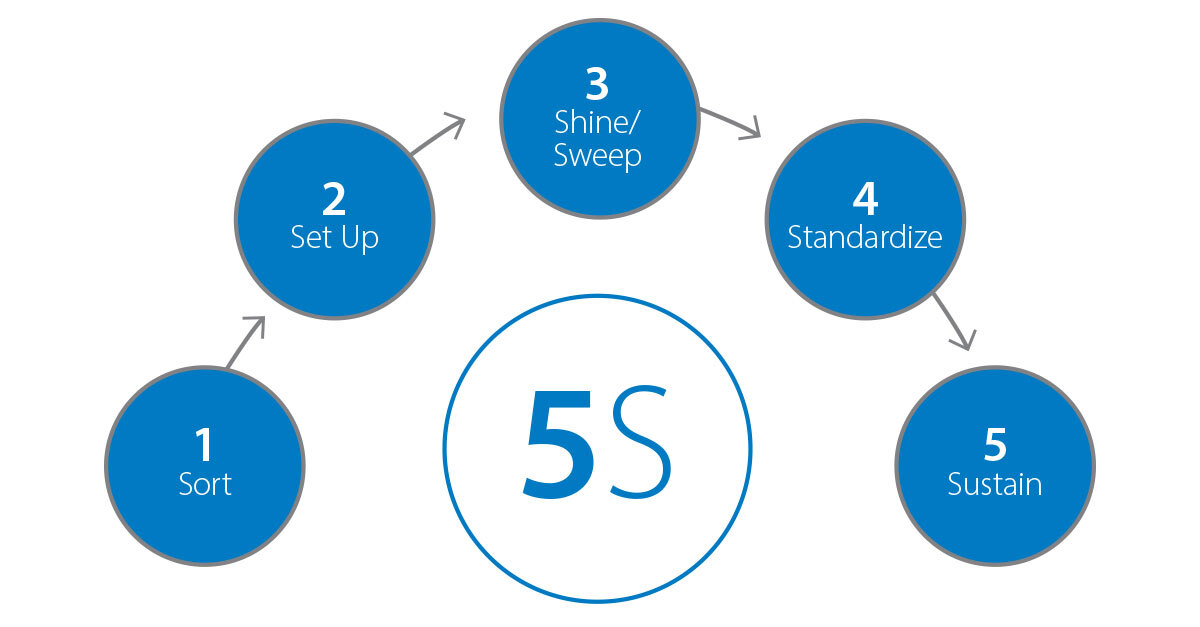

To tackle this problem, the LEAN process is used, a 5-step solution that reduces and eliminates this disarray, inefficiency, and waste, and aims to create a sustainable, productive, clean environment that keeps employees happy and healthy. LEAN is a process that uses these steps to make facilities more efficient. It consists of the following steps: Sort (separate tools and parts from unnecessary material), Set Up (organize what’s left), Shine/Sweep (clean up the work area), Standardize (schedule regular cleaning), and Sustain (create the habit of following these steps).

A LEAN methodology in your facility can also help you comply with government regulatory standards.

A LEAN Process Can Boost Efficiency

With disarray, employees can feel the frustration of wasting their most valuable resources - their time and energy. As an example of this, Toronto Airport has multiple custodial rooms throughout its facility. It can take anywhere from 15-20 minutes for cleaning staff and employees to get to their main supply room. That’s 40 minutes wasted getting to and from the main supply room, not to mention the time it takes to sort through the myriad of products scattered in a disorderly fashion. This can translate into upwards of 1-2 hours lost in an 8 hour day. Fortunately for the Toronto Airport, they have applied our LEAN methodologies and eliminated this waste.

By implementing a cleaning program closer to where it is needed and having it organized in a way that reduces visual noise, productivity is increased, frustration is nullified, and employee well-being is managed. With LEAN, everything is labeled and in a specific spot for familiarity to reduce the friction between finding the tools for the job and actually completing it. This can all have a compounding effect on your bottom line.

A LEAN Environment is a win-win... win

With LEAN, you can save time and money, while keeping your staff and employees content. Creating a LEAN process in your facility is pivotal in increasing efficiency and with the appropriate training, accessories, and knowledge, you too can create a LEAN environment that benefits all parties involved.